Engine Lubrication Systems

Engines have very large number of moving components. These components move relative to each other and bear huge amount of friction. This friction generates heat and is responsible for wear and tear of the Engine Components. In many cases, the wear and tear may get so severe that it starts affecting the engine performance. Also, the heat generated due to friction may get such higher that, it may even weld the contact surfaces together. Hence, we need to prevent the direct contact between the moving components of the Engine. This is done by providing proper lubrication to the engine components and this lubrication is done using Engine Oil. This lubricant is circulated all across the engine through Oil galleries and other mechanisms.

Functions Of Engine lubrication System

Apart from lubricating the Engine Components, the engine lubrication system performs several other vital functions. Many of those functions are essential for engine performance and its life. Let's look at some of those functions one by one.

- Engine Oil sticks to the surface of Engine Components and prevent surface to surface contact between them .

- Engine Oil helps in removal of heat generated due to friction between rhe components.

- Engine Oil prevents the corrosion of the Engine Components and hence, increase their life.

- The Engine Lubrication System Circulates the Engine Oil across the whole engine, hence it helps in cleaning of all the components.

Types Of Engine Lubrication Systems

Depending upon the need and the type of engine, there may be several types of Engine Lubrication Systems. Every system has its own advantages and disadvantages.

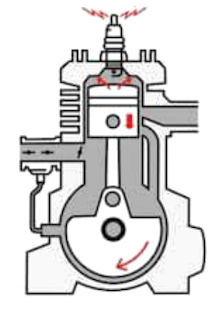

Mist Lubrication System

Mist lubrication system was used for lubrication in 2-Stroke Engine. In this system of lubrication, the Engine Oil was mixed with the fuel and supplied to the Engine. This mixture was converted in to fine vapors in the Carburetor. This fine mixture of Fuel and Lubricant forms mist. This mist helps in Lubricating the components inside the Engine. This system is very simple and do not require components such as lubricating pump, Lube Oil Filter or Oil sump. However, one major disadvantage of this system is burning of Engine Oil along with the fuel. This causes a lot of pollution and also reduces the efficiency of the engine.

Pressure Feed Lubrication System

Types Of Pressure Feed Lubrication System

Depending upon the size of Oil sump, the Pressurised Lubrication System is further classified into:

- Wet Sump Lubrication System

- Dry Sump Lubrication System

Wet Sump Lubrication System

This type of Lubricating system is very common and is used in most of the modern vehicles. They consist of a large size Oil Sump to store the Engine Oil. The Oil from the sump is supplied to the Oil galleries through an Oil Pump. The Wet Sump Lubrication System is simple in design and requires very less number of components as compared to the Dry Sump Lubrication System. They also do not need hoses and other pipes to supply Oil to the Oil tank as their Oil is stored in their Sump only. The large size of the Oil sump increases the size of Engine, shifting the centre of gravity upwards.

Dry Sump Lubrication System

Dry Sump Lubrication System is generally used in sports cars. This system consists of a smaller Sump for temporary Engine Oil collection. The Oil from the Sump is supplied to a storage tank using scavenging pump. The Oil Storage Tank consists of perforated baffle plates to separate out air from the Engine Oil. The Storage Tank is not the part of Engine and lies away from it. From storage tank the Oil is supplied through main Oil Pump to Oil filter and than to intercooler. The Intercooler is used to keep the Engine Oil cool which is necessary to maintain its viscosity. This system can store a large amount of Engine Oil in its Oil storage tank, without increasing the engine size. This system maintains a continuous and pressurised supply of lubricant necessary for performance cars. This system also prevents the drag and friction losses which occurs due to splashing of engine oil by the Connecting Rod. However, this system is very complex and increases the overall cost of the vehicle.

Friends this was a small overview of Engines Lubrication System. We hope you enjoyed it. More more interesting information please subscribe yo our newsletter.

Leave a Comment