Components Of An Internal Combustion Engine

Internal combustion engines or IC engines are the prime movers which convert the chemical energy of fuels into mechanical energy. They are given the name 'internal combustion engines' because their combustion chamber is their integral part. Unlike the external combustion engines, whose combustion chamber lies away from their prime mover. The invention of IC engines was one of the greatest achievements of human history. They have been one of the key reasons for the huge developments we have made. In this post, we will look at the different components of an IC engine, in order to develop a basic understanding of their working. The whole engine can be divided into three sections for the purpose of the study:

Head section

The Head Section contains parts like Inlet and Exhaust manifolds, Spark Plug, Valves and valve actuation mechanism, & camshaft

Block Section

The block Section consists of parts like cylinder block, cylinder lining, cooling jacket, piston and connecting rod.

Crank Case

Crankcase houses crankshaft and the oil sump. It also has the oil pump to circulate the engine oil across the engine.

Now, let's discuss all these parts in detail

Cylinder Block

The cylinder block is the structure which houses the engine cylinders. It is a solid block of metal inside which cylinders are carved out. It may also have a cooling jacket to store coolant. It is generally made of cast iron. It may also be made from Aluminium Alloys. The cast iron blocks are cheap and easy to manufacture. At the other hand, Aluminium blocks are lighter and have better heat conduction capacity necessary for proper cooling.

Cylinder Liner

The reciprocating piston rings rub against the cylinder wall and generate a huge amount of friction. This friction may damage the cylinder walls. Hence, liners are provided on the inner surface of engine cylinders, to prevent them from wear and tear. The liners are not the integral part of cylinder blocks, they can be replaced if they are worn out. This saves the vehicle owner from the huge cost of replacing the whole cylinder block. The liners are generally made from very hard materials, as they have to bear huge temperature and friction. The material generally used for them are Nickel and Chromium-based alloys of iron. They can be of two types depending upon their design:

1. Wet Liner

They remain in direct contact with the coolant.

2. Dry Liner

They do not have any contact with coolant.

Cylinder Head

It is the topmost part of the engine and is mounted over the cylinder block. A gasket is provided between their mating surfaces to prevent the leakage of engine oil and the unburnt Air-Fuel mixture. If you do not know what the gasket is? Just look at the image below.

Cylinder head houses components like Inlet and exhaust valves, spark plug, inlet pipe, camshaft etc. They have to bear huge temperature of combustion, hence they are made from Aluminium alloys. Aluminium being a good thermal conductor, dissipates the heat easily and keep the head cool.

There are two valves in each cylinder. One for intake and the other for exhaust. The valves are operated by camshaft through valve actuation mechanism. The valves continuously open and close in order to facilitate the intake and exhaust of the gases. The valves have to bear a huge amount of heat and dynamic forces. Hence they need to be made from a strong material such as steel. The intake valve is kept larger than the exhaust valve. The reason for keeping intake port and intake valve larger is to let a large amount of air or Air-Fuel mixture come in. The exhaust valve is kept smaller as the pressure inside the combustion chamber becomes extremely high after the power stroke. This pressure is sufficient enough to throw the exhaust gases out of the engine cylinder.

Camshafts are rotating components which contain cam lobes. The actuation of inlet and exhaust valves is done through these lobes. The camshafts are made by surface hardened steel. The lobes are precession machined to maintain the accuracy in valve actuation. The camshaft is rotated by the crankshaft using timing chain.

Piston

The piston reciprocates inside the engine due to the forces generated inside the combustion chamber. This reciprocating motion is responsible for intake and exhaust of the gases from engine cylinder. The piston receives the explosive forces generated due to the burning of fuel and convert it into mechanical energy by rotating the crankshaft. The piston is connected to the crankshaft through a connecting rod. It is generally made of aluminium alloys. The aluminium pistons are lightweight and have good thermal conductivity. The lighter piston can reciprocate easily and with greater speed. Higher thermal conductivity helps them to conduct the heat to the cylinder walls, keeping them cool. One problem with aluminium is that it has a very high thermal expansion coefficient. Hence, a proper clearance must be given between the piston and the cylinder walls. In case of less clearance, the thermal expansion of piston may also cause the engine to seieg.

Piston rings

Piston rings are fitted around the piston to prevent the direct contact between the piston and the cylinder walls. The direct contact between the piston and the cylinder walls will cause a huge amount of friction during the operation. Hence, the rings reduce the friction and wear & tear of the piston surface. There are generally 3 rings around the piston. The two upper rings are called compression rings and the one at the bottom is called the oil ring. The compression rings prevent the leakage of combustion products to the crankcase. The oil ring helps in scraping the excess oil from the cylinder walls.

Connecting Rod

The connecting rod connects the piston and the crankshaft. Its small end is connected to the piston using gudgeon pin and its big end connected to crankpin journal. It converts the reciprocating motion of the piston into rotational motion of the cranks shaft. It bear a huge amount of dynamic forces during this process. Connecting Rods are generally made of forged steel or aluminium alloys. Forged steel connecting rods are stronger and can bear a huge amount of dynamic forces. The aluminium connecting rods are lifter and can absorb a significant amount of impact forces.

Crankcase

The crankcase is a casing which consists of the crank shaft and oil sump. It is generally manufactured in two parts i.e. crankcase left and crankcase right. These two parts are assembled together to form the complete crankcase. It contains holes at both sides in which bearings are fitted to mount crankshaft.

Crankshaft

The crankshaft is the component which is rotated by the piston to convert chemical energy of combustion to mechanical energy. Its both ends are fitted in crankshaft bearings on the crankcase. The big end of the connecting rod is fitted on the crank pin. It converts the reciprocating motion of the piston into the rotational motion of the crankshaft. The flywheel is mounted on the one end of the crankshaft. Its other end is connected to the transmission system through gears. This arrangement helps in transmitting the power to the wheels from the engine. The crankshaft contains oil gallery all along its cross-section, to lubricate the bearings and crank pin. Balancing weights are attached at the opposite side of the crank pin. This helps in balancing the dynamic forces generated due to force transfer from connecting rod to the crankshaft. They are also connected to the camshaft through timing chain. It helps in rotating the camshaft which further facilitates the valve actuation.

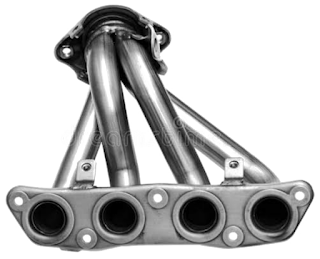

Intake Manifold

Intake manifold helps in the distribution of air to the various cylinders of a multi-cylinder engine. It lies between the throttle body and the engine cylinders. The components like Intake air temperature sensor, MAP sensor, Idle Air Control valve and Fuel injectors are mounted on it. It is generally made of Cast Iron or Aluminium alloys.

Exhaust Manifold

Exhaust Manifold lies in between engine cylinders and the muffler. It helps in collection of combustion products from the different cylinders of a multi-cylinder engine. The components like Oxygen Sensors are also mounted on the exhaust manifold. They are generally made of Cast Iron or Stainless Steel.This was a small overview of different components of an internal combustion engine. There are many other components which could not be mentioned here. However, we have included all the major components and their working. This information would help in increasing your basic understanding of the internal combustion engines. We hope that you enjoyed reading the post. Please give your feedback in the comment section below.

Leave a Comment